Product overview: YGM305 is an intrinsically safe and explosion-proof product specially designed for gas explosive environment, which has passed the national explosion-proof certification. Its explosion-proof signs are Exd [ia Ga] IIB T4 Gb (explosion-proof box), Exd ia IIB T4 Ga (probe assembly), and it complies with the national standards of GB3836.1-2010, GB3836.2-2010, GB3836.4-2010, and GB3836.20-2010. YGM305 probe part is made of high temperature resistant stainless steel probe rod, which can be used in the high temperature environment of 200 ℃ at most; The sensor part is designed with intrinsic safety and low power consumption. It is isolated from the main control circuit by zener type safety barrier. The enclosure is a professional explosion-proof case. The explosion-proof function is added under the condition of intrinsic safety and low power consumption, which makes the use of this product more safe and reliable.

Application field: wheel hub polishing workshop, pharmaceutical plant and other places with explosion-proof requirements

Main features: stable performance, strong anti pollution ability, high cost performance

Measuring range: selected according to the on-site air volume (wind speed)

Accuracy: ± 4% FS (under stable gas flow rate)

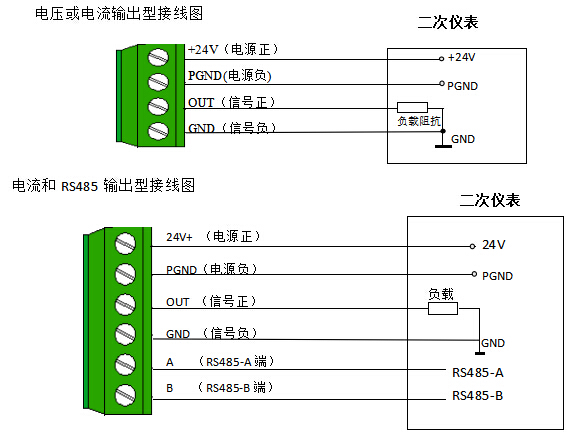

Signal output: current output type: 4 ~ 20mA (three wire system), load resistance RL ≤ 500 Ω

Voltage output type: 0 ~ 10V (three wire system), load resistance RL ≥ 10K Ω

RS485 output: standard ModBus RTU

Response time: T90 ≤ 3s

Power supply: 20~28VDC

Electrical connection: M16 × 1.5, cable diameter: 4-8mm

Enclosure protection grade: IP65

Explosion proof sign: Ex d [ia Ga] Ⅱ B T4 Gb (explosion-proof box) Ex ia Ⅱ B T4 Ga (probe assembly)

Working pressure: less than 1 Bar

Working temperature: transmitter: - 20~+40 ℃

Probe rod: - 40~+200 ℃

Storage environment: temperature - 20~60 ℃, humidity 0~85% RH

Wiring diagram:

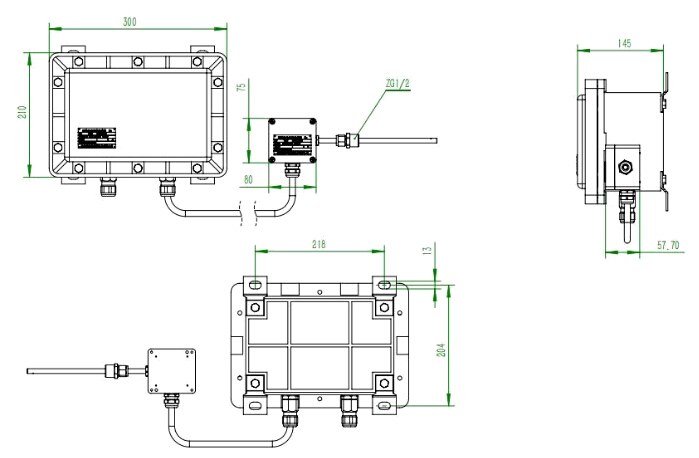

Structural dimension drawing:

Model Selection Guide:

| Serial No |

Instrument specifications |

YGM305- | ||||||||||||

| 1 |

Confirmation of installation mode |

Split type | 2 | |||||||||||

| 2 | Measurement method | Rhombic average velocity measuring piece | A | |||||||||||

| Purgeable anti pollution test piece | B | |||||||||||||

| High temperature stainless steel probe rod | C | |||||||||||||

| 3 | output | 4~20mA | 01 | |||||||||||

| 0~10V | 02 | |||||||||||||

| 4 | accuracy | ±6%FS | 06 | |||||||||||

| ±4%FS | 04 | |||||||||||||

| 5 | Wind direction selection | one-way | LD | |||||||||||

| two-way | LB | |||||||||||||

| 6 | Length of sampling hose | 1m | 10 | |||||||||||

| 1.5m | 15 | |||||||||||||

| 3m | 30 | |||||||||||||

| Special customization | XX | |||||||||||||

| 7 | Medium temperature | -40~+80℃ | 408 | |||||||||||

| -40~+120℃ | 412 | |||||||||||||

| -40~+160℃ | 416 | |||||||||||||

| -40~+200℃ | 420 | |||||||||||||

| 8 | Effective pipe size(mm) | 100~200 | 200 | |||||||||||

| 201~280 | 280 | |||||||||||||

| 281~320 | 320 | |||||||||||||

| 321~390 | 390 | |||||||||||||

| 391~480 | 480 | |||||||||||||

| 481~580 | 580 | |||||||||||||

| 581~780 | 780 | |||||||||||||

| 781~960 | 960 | |||||||||||||

| 961~1150 | 115 | |||||||||||||

| 1151~1350 | 135 | |||||||||||||

| 1351~1550 | 155 | |||||||||||||

| 1551~1750 | 175 | |||||||||||||

| 1751~1950 | 195 | |||||||||||||

| 1951~2150 | 215 | |||||||||||||

| 2151~2530 | 253 | |||||||||||||

| Special customization | XXX | |||||||||||||

| 9 | Mounting accessories |

Inner square hole flange connection (Applicable to measurement methods A and B) |

A (The effective pipe size<320mm is single flange, and>320mm is double flange) |

|||||||||||

|

Metal flange connection (Applicable to measurement mode C) |

T (Recommended square air duct) |

|||||||||||||

|

Threaded connection (Applicable to measurement mode C) |

S (Recommended round air duct) |

|||||||||||||

| 10 | Pipe section size | (Specific values provided by the customer) | **m2 | |||||||||||

| 11 | Maximum air volume of pipeline | (Specific values provided by the customer) | ** m3/h | |||||||||||

Note: When special customization is selected, some technical parameters will also be inconsistent with the technical parameters in this book. Please make a special note when ordering.

1. The maximum length of sampling hose is 3m.

2. If 480 is selected as the effective pipe size code, it means the minimum effective pipe size (MIN) 391mm~the maximum effective pipe size (MAX) 480mm.

Description of effective pipe size: 1. If the outer diameter of the circular pipe is 100mm and the inner diameter is 80mm, the effective pipe size is 80mm;

2. If the rectangular pipe is 500mm horizontally, the insulation layer is 50mm, and the wall thickness is 5mm, the effective size of the pipe is 500-50 * 2-5 * 2=390mm.

Ordering example:

| YGM305-2B0106LD10408480A | ||

| Confirmation of installation mode | Split type | |

| Measurement method | Purgeable anti pollution test piece | |

| output | 4~20mA | |

| accuracy | ±6%FS | |

| Wind direction selection | one-way | |

| Length of sampling hose | 1m | |

| Medium temperature | -40~+80℃ | |

| Effective pipe size(mm) | 391~480 | |

| Mounting accessories | Inner square hole flange | |

| Pipe section size | **m2 | |

| Maximum air volume of pipeline |

** m3/h |

|

Your location:

Your location: